If you own a Dodge Cummins, you may have encountered the P00AF code at some point. This code is related to the turbocharger and can affect the engine’s performance, causing it to run poorly or even stall.

In this article, we’ll explain what the P00AF code means, what causes it, and how to diagnose and fix it.

To diagnose it, you will first have to inspect a few different components (turbo boost actuator, turbo wastegate, the wiring harness, turbo vacuum lines, and even the PCM).

Your approach towards fixing the problem and clearing the code is dependent on what exactly needs doing. Sometimes, the problem can be solved by simply cleaning the actuator, but replacing the actuator is usually the best thing to do.

The P00AF code is indeed serious, which is why you shouldn’t drive the car before fixing it.

If you are not 100% confident in your abilities, it would be best to leave these tasks to a trained and experienced professional, even if that means spending a few hundred dollars extra.

So, whether you’re a seasoned mechanic or a Cummins owner with little automotive knowledge, keep reading to learn more about this common issue.

What is the P00AF code on a Dodge Cummins?

The P00AF code on a Dodge Cummins refers to a fault in the turbocharger boost control system (“Turbocharger/Supercharger Boost Control A Module Performance).

Specifically, it indicates a problem with either the turbocharger boost control module or its associated sensor.

The letter “A” does not only mean that the problem is associated with a specific component, but also a potential error somewhere in the circuit system.

The actuator within the system picks up a problem and communicates that problem to the PCM which prompts up the Check Engine Light and records the P00AF DTC.

This fault code may cause the vehicle to go into a reduced power mode to protect the engine.

Symptoms of P00AF Code on a Dodge Cummins

- Check Engine Light (CEL)

- Limp Mode (Reduced Engine Power)

- Poor Acceleration

- Poor Fuel Economy

- Turbocharger Lag

- Strange Noises

- Engine Stalling

Check Engine Light

At the very onset of this problem, you are likely going to be greeted with the good old CEL.

This in itself is not enough to point toward a specific issue but should serve as a wake-up call to inspect your engine and scan it with an OBD-II scanner.

Limp Mode (Reduced Engine Power)

When the vehicle’s PCM/ECU detects a fault (powertrain error-detecting code) that could potentially cause powertrain damage, it may activate the limp mode, which limits the engine’s power and speed.

This is typically accompanied by a warning light or message on the dashboard, such as “Reduced Engine Power”, “Limp Mode”, or “Service Now”.

The fact that the car limits the engine and turbocharger output should serve as an obvious sign that something with either the turbo or the engine is the problem.

Poor Acceleration

When the turbocharger system isn’t functioning properly, the engine may struggle to generate enough power and torque, resulting in slower acceleration and reduced performance.

As such, poor acceleration can be an obvious sign that either your turbochargers, your boost control solenoid, or some of your system wires are to blame.

Poor Fuel Economy

The P00AF DTC indicates that the boost pressure is higher than the manufacturer-specified limits for a certain period of time and thus can lead to poor fuel economy.

When the turbocharger or supercharger produces excessive boost pressure for an extended amount of time, it causes the engine to burn more fuel to compensate for the increased air intake.

This results in poor fuel economy, as the engine is using much more fuel than initially needed.

Turbocharger Lag

Turbocharger lag refers to a problem where the turbo either can’t make enough boost or fails to do so until it reaches abnormally high RPM levels.

As the P00AF code refers to inconsistent boost pressure, it could also mean that your turbocharger isn’t able to deliver much-needed boost when expected.

Strange Noises

When the turbochargers or superchargers system is not functioning properly, it may produce unusual noises that can be heard inside the cabin of the vehicle.

These whistling, whining, and rattling signs are often associated with a faulty turbocharger system that either creates too much or too little boost, an issue that points directly to the P00AF DTC.

Engine Stalling

When the turbocharger system is not functioning properly, it may not be able to provide the required boost pressure to the engine, which can cause the engine to stall.

This can be particularly noticeable when the engine is under load, such as when accelerating or towing a heavy load.

The Causes of the Error Code P00AF

The most common causes of the P00AF code are:

- A problem with the turbo control solenoid or turbocharger (damaged, worn out, corroded, stuck, etc…)

- A problem with the wiring, connectors, pins, circuit, and grounds (damaged, worn out, corroded, stuck, etc…)

- A problem with the ECM/PCM

- A problem with the turbocharger wastegate

- A problem with the Boost Control Module

- Excessive output soot in charger vanes (Boost levels stuck at high/low)

How serious is code P00AF on a Dodge Cummins?

The P00AF DTC is considered a moderately serious issue that should be addressed as soon as possible to prevent further damage to the engine.

Continuous flexing of the turbocharger (supercharger) vanes may cause considerable damage to other components such as the push rods or engine rockers.

The general rule of thumb is to never drive a car if it prompts up a DTC before you know exactly what is wrong.

Is it safe to drive with the P00AF code?

It is generally not recommended to drive your vehicle with the P00AF code on a Dodge Cummins engine.

On the one hand, if the cause of the code is a minor issue, such as a faulty boost pressure sensor or a clogged air intake, you can drive your car for short distances only.

On the other hand, if the problem is related to a more serious problem with the inner turbocharger vanes, do not drive the car at all.

How to Diagnose the P00AF Code

Diagnosing the P00AF code thoroughly requires a broad understanding of car diagnostics and inner mechanics.

If you are not fully confident in your tools and your abilities, you ought to take your car to an experienced mechanic for a proper diagnosis and solution to this problem.

Always be sure to consult yourself with a Dodge-specific repair manual as the P00AF code requires a completely different approach depending on the automaker.

Also, make sure to turn the car off and let it cool off before you do anything as the forced induction (FI) system can get really hot during operation.

- Step 1: Check for other potential DTCs via an OBD scanner.

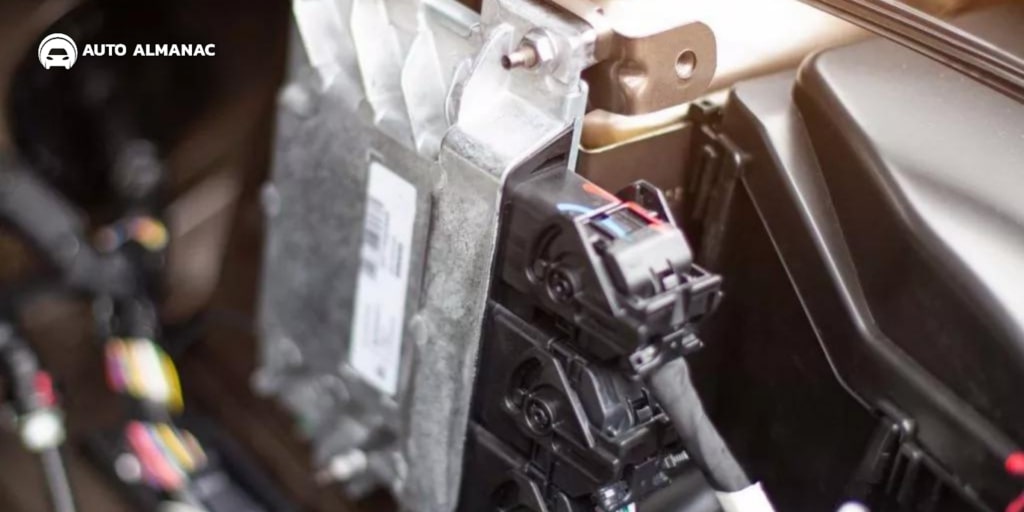

- Step 2: Look for the boost control actuator, which tends to sit directly on top of the turbo.

- Step 3: Check if the pneumatic rod actuator properly opens and closes during operation and that there are no visible signs of damage, wear and tear, or corrosion anywhere on the actuator.

- Step 4: Check the wiring, grounds, pins, and connectors for any signs of rust, dirt, and especially heat damage.

- Step 5: Use a multimeter to check the resistance and if all of the wires, connectors, and pins are providing current.

- Step 6: Test out the boost control module for resistance and damage/water ingress.

- Step 7: Check all of the turbocharger vacuum lines for leaks as leaks can cause loss of boost pressure.

- Step 8: Test the turbo wastegate to see if it’s properly opening and closing.

- Step 9: Test out the PCM

How to Solve P00AF Error Code on Dodge Cummins

These are the most common methods of getting rid of the PA00F code for good:

Malfunctioning Boost Control Actuator

After carefully examining the boost control actuator and seeing that its inner mechanics are in shambles, there are two things you can do.

You can either clean it and hope for the best or you can simply replace it immediately and not risk any further damage to the rest of the powertrain.

Cleaning the Actuator

Cleaning the turbo boost control actuator may improve its performance if it has become dirty or clogged with debris.

However, if the actuator is damaged or has mechanical issues, cleaning it may not solve the problem. Properly cleaning the rods is likely going to reveal if there are any major signs of damage within the actuator.

Either way, be sure to use an appropriate cleaning solution and follow the manufacturer’s recommendations carefully.

Replacing the Actuator

If the actuator is visibly damaged or not working after a thorough clean, there is only one thing you can do to fix it, and that’s to just replace it.

- Step 1: Make sure that the engine and the turbocharger have had enough time to cool down before you start working on them.

- Step 2: Carefully disconnect the electrical connector and vacuum lines from the boost control actuator.

- Step 3: Using a wrench or socket set, remove the bolts that hold the boost control actuator in place. Be careful not to damage any surrounding components.

- Step 4: Carefully install the new boost control actuator in the same location as the old one. Tighten the bolts to the manufacturer’s recommended torque specifications.

- Step 5: Carefully reconnect the electrical connector and vacuum lines to the new boost control actuator. Make sure that all connections are secure and away from hot turbo and engine components.

- Step 5: Start the engine, clear the code, and test the turbocharger to ensure that the boost pressure is within the manufacturer’s recommended specifications.

Wiring, Connector, and Circuit Issues

If you took your time to test the resistance of the entire wiring harness that controls the boost pressure and found that some of the wires have failed, you will have to replace them.

Always be sure to disconnect the battery whenever you are planning to replace a specific wiring harness to avoid any potential harm to the car or yourself.

ECM/PCM Problems

If the entire process failed to highlight specific issues within the turbocharger (supercharger) system, it is a good idea to focus your attention on the PCM.

This is especially if you come across multiple other symptoms that severely affect your drivability.

Working with a PCM is rather tricky and requires time, focus, and precision, so do not attempt to diagnose or fix the PCM yourself if you are not 100% aware of what you need to do.

If the PCM can’t be saved by replacing some of its inner circuitry or its wiring harness, you will have to replace it with a new one and also update it to the correct software version.

Boost Module Problems

If the problem came back to a water-damaged boost module (which is often the case) you will have to replace it with a new one.

- Step 1: Disconnect the battery. This will help prevent any electrical damage or injury during the replacement process.

- Step 2: Carefully disconnect the electrical connector and vacuum hoses from the boost module.

- Step 3: Using a wrench or socket set, remove the bolts that hold the boost module in place. Be gentle and don’t damage any of the nearby components.

- Step 4: Carefully install the new boost module in the same location as the old one. As always, tighten the bolts to the manufacturer’s recommended torque specifications.

- Step 5: Carefully reconnect the electrical connector and vacuum hoses to the new boost module, reconnect the battery, clear the code, and test it all out.

Leaking Vacuum Lines

If your troubleshooting process concluded that there is a leak in your turbocharger vacuum lines, you will have to replace them.

- Step 1: Carefully remove the vacuum line from the turbo boost actuator and the intake manifold.

- Step 2: Be sure to use the correct replacement size and type of vacuum line for your vehicle. It is also recommended to use a high-quality vacuum line that is resistant to heat and other environmental factors.

- Step 3: Once the new vacuum line is in place, reconnect it to the turbo boost actuator and the intake manifold.

Turbocharger Wastegate Problem

Even though this is not often the case, a faulty turbocharger wastegate can also cause this problem. To fix it, be sure to follow these steps to replace it:

- Step 1: Disconnect the battery. This will prevent any electrical damage or injury during the replacement process.

- Step 2: The wastegate is usually located on the turbocharger, so it will need to be removed first.

Use a wrench or socket set to remove any bolts or clamps that hold the turbocharger in place. Carefully disconnect any electrical or vacuum lines that may be connected to the turbocharger.

- Step 3: Using a wrench or socket set, remove the bolts that hold the wastegate in place. Be careful not to damage any surrounding components.

- Step 4: Carefully install the new wastegate in the same location as the old one. Tighten the bolts to the manufacturer’s recommended torque specifications.

- Step 5: Repeat the first two steps backward, clear the code, and test out the system.

How much does it cost to solve the error code P00AF?

The costs of fixing the P00AF code are highly dependent on what needs doing. Here are the rough cost rundowns of the most common solutions:

| Item | Cost |

| A New Actuator | $80 to $150 |

| A New PCM | $500 to $1,500 |

| A New Vacuum Line | $20 to $80 |

| A New Wastegate | $60 to $150 |

Common Mistakes While Solving the P00AF Code

These are the most common errors made by technicians while resolving the P00AF code:

- Failing to inspect the turbocharger’s inner mechanical workings

- Failing to actually validate the P00AF code

- Not clearing the code after fixing the problem

- Cleaning a damaged actuator

- Replacing the turbocharger or the PCM before diagnosing all of the linked components.